Capstone: Carbon Fiber Bicycle

Design Outline

To create a full vertically integrated manufacturing process for custom carbon fiber bicycles, using a range of digital fabrication techniques.

Technical Sub-Systems

To achieve this, I could not just build a bike. I had to build the factory first. I engineered my own manufacturing equipment and software control logic to make this workflow possible.

Manufacturing Methods

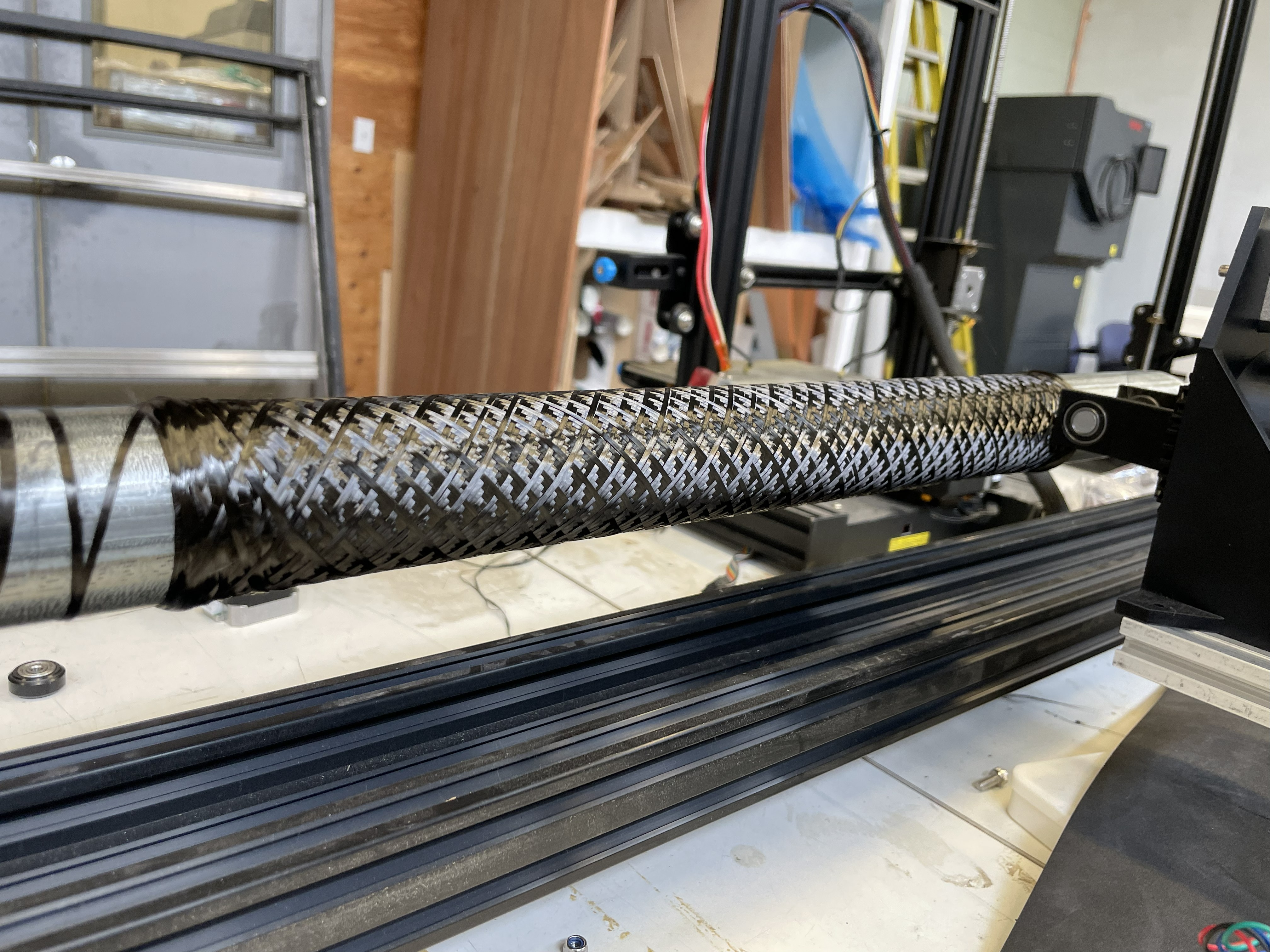

1. Automated Filament Winding

I utilize a custom 3-axis winder to produce carbon tubing. This allows me to tune the stiffness and compliance of the frame via code rather than manual layup.

2. Trapped Rubber Molding

Moving away from expensive metal molds, I utilize 3D printed tooling (High-Temp PLA) paired with heat-expanding silicone mandrels to consolidate the composite parts under high pressure.

3. Hybrid Metal Lugs

By utilizing Metal Powder Casting for junctions, I can create complex, custom geometries without the massive tooling costs of traditional monocoque molds.

Follow the sub-project links above for detailed engineering logs.